SMS code login

Password Login

Get SMS verification code

Installation and Disassembly

2023-03-27

BYB rolling bearings are precision products, which require special care before and during assembly. The trouble free operation of bearings is largely related to the quality of assembly

Save

Rolling bearings should be stored in a dry dirt warehouse, with a temperature of normal temperature and a humidity not higher than 65%. BYB rolling bearings have been stored and treated before being supplied to the user (adding rust inhibitor on the basis of mineral oil or packaging with dry vapor phase corrosion inhibiting VCI paper), so do not open the packaging too early before direct assembly. If only a few bearings are taken out of a package packed with volatile anti rust paper for use, then all bearings should be immediately wrapped after removal, as the protective vapor phase of VCI paper can only be maintained under closed conditions. Bearings removed from the packaging must be immediately filled with grease or oil

Sealed bearings filled with grease should not be stored for more than three years, even if stored in a suitable environment. Grease that has aged due to long-term storage or adverse weather conditions must be replaced during assembly

Cleaning

The antirust oil of BYB rolling bearings is compatible with mineral oil based greases and lubricants, and can be mixed with each other. Therefore, special treatment is not required before assembly. However, if synthetic lubricating oil or high-temperature or low-temperature lubricating grease is used, or if the working humidity exceeds+90 ℃ or if it is already dirty, the bearings should be cleaned

Many cleaning agents can be used to clean the grease in bearings and clean bearings

Inorganic cleaning agents are used in the form of aqueous, alkaline solutions. The humidity of the cleaning tank should be from+70 ℃ to+80 ℃, and the parts must remain in the tank until they reach the temperature in the tank. They should then be immersed in the dewatering tank. Alkaline solutions cannot be used to clean bearings with aluminum cages. Organic cleaning agents, such as acids, anhydrous kerosene, and benzol (non automotive gasoline), are also suitable as cleaning media

Chlorinated hydrocarbons, such as trichloroethylene or perchloroethylene, are not recommended as cleaning media because they increase the risk of corrosion. During cleaning, there should be at least two cleaning tanks, one for initial cleaning and the other for final cleaning. After cleaning, the bearings should be immediately greased or lubricated

Assembly

The bearing assembly area should be kept clean and free of dust and debris, as the intrusion of dirt into the bearing will have a harmful impact on the bearing life. Before assembly, the bearing housing hole and shaft should be inspected for dimensional tolerance, geometric accuracy, and cleanliness

The bearing collar should be installed on a press with the aid of an auxiliary sleeve. The assembly sleeve should be properly selected and able to fully press the end face of the bearing collar. If you do not have a press, you can tap the center of the assembly sleeve. Assembly forces must not be transmitted through rolling elements. Direct hammering on the bearing collar should also be avoided

If a small amount of lubricating oil or solid lubricant is applied to the mating surface, and there is 10°- 15° The assembly of the inner and outer rings is easier by using an induction heater to heat the inner or bearing before assembly. This is the easiest method for tight fitting. If this heater cannot be used, the bearing can be heated in an oil bath or in a heating box to about+80 ℃

Cooling is not recommended here to install the bearing into the bearing housing, as condensed water may cause corrosion on the bearing and bearing mating surfaces. For bearings with special assembly requirements, the technical notes before the dimension table will explain them. After assembly and lubrication of the bearings, it is recommended to carry out a test run to check whether the bearing device is operating properly

Disassembly

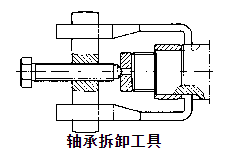

The disassembly of bearings should be considered in the design of bearing devices. If the bearings are selected for mating assembly, corresponding grooves should be provided on the shaft or in the bearing seat hole to allow disassembly tools to proceed

If the removed bearing is still ready for reuse, it should be avoided to directly hammer the bearing collar and prevent the removal force from being transmitted through the rolling element. Subsequently, the removed bearing should be carefully cleaned, preferably in the disassembled state